Tobacco manufacturers are required by law to provide graphic warning labels on all tobacco products. This article discusses what these labels entail, why they’re necessary, and how they may affect your bottom line if you sell tobacco products. You can view more information on this url.

Contains at Least 10 – 20 Sticks Each Pack

Each pack of tobacco contains 20 sticks or non-reusable papers for smoking. They are required by law to provide graphic warning labels on all tobacco products. Graphic warning labels are large, bold health warnings covering most of the package front and back.

Each pack of tobacco contains 20 sticks or non-reusable papers for smoking. They are required by law to provide graphic warning labels on all tobacco products. Graphic warning labels are large, bold health warnings covering most of the package front and back.

You will notice that these labels are very different than traditional cigarette packaging. The goal of the graphic warning label is to educate smokers about the health risks associated with smoking and discourage them from doing it; particularly, among young people who may not have realized how dangerous cigarettes can be.

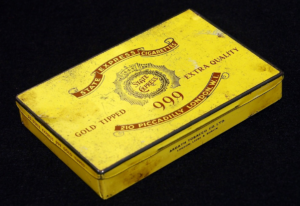

Brands Must Be No Larger Than 40% Of the Area

The brand name on the packaging must be no larger than 40% of the area. The font size for all other text on the package must also be no smaller than 12 points. This ensures that all consumers see and read the health warnings before making a purchase. The labels are placed on the top of the package, and they must be visible from a distance. They contain images and text that depict the harmful effects of smoking. Some of these warnings include cancer, heart disease, and stroke.